Laser cleaning

Laser cleaning

- The production of a large quantity of thermal energy

- The creation of shock waves

- These three effects result in the sublimation and ejection of coating particles or residues.

No substrate alteration

Ecological solution

Powerful cleaning

Principle

In the case of organic soils, these will be sublimated by the heat energy of the laser pulses. The high energy absorbed creates a highly compressed plasma (ionised gas out of equilibrium) which expands creating a shock wave.

Contact us by phone for any questions: +352 671 270 596

Applications

Get a free consultation

Contact us by phone for any questions:

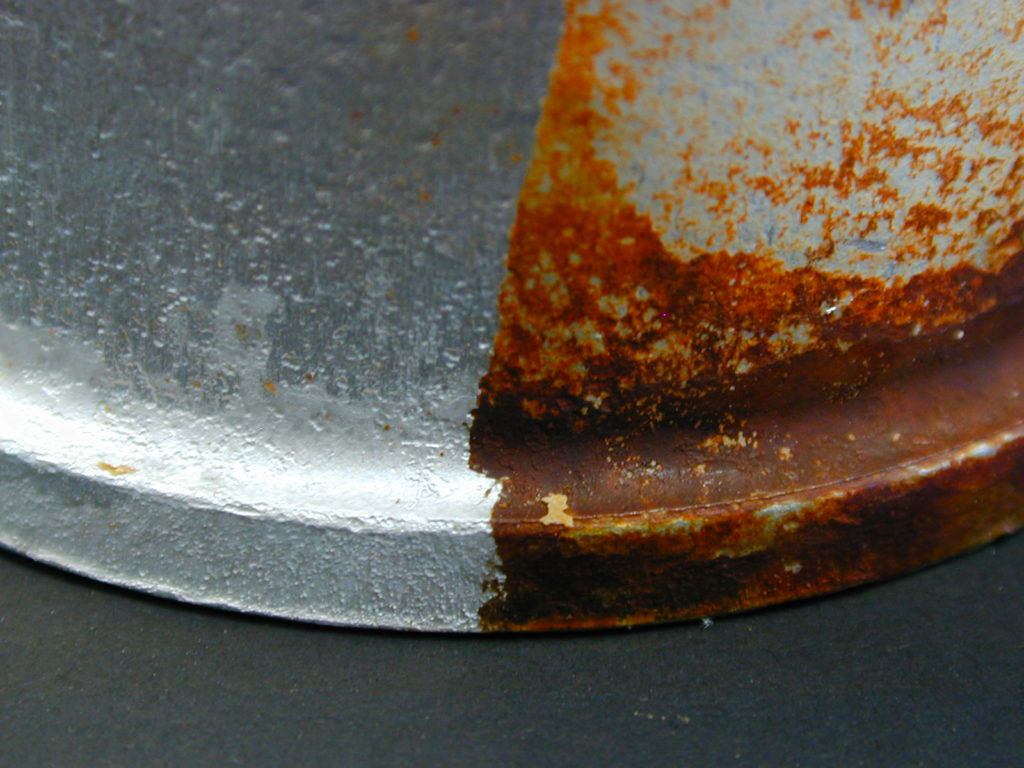

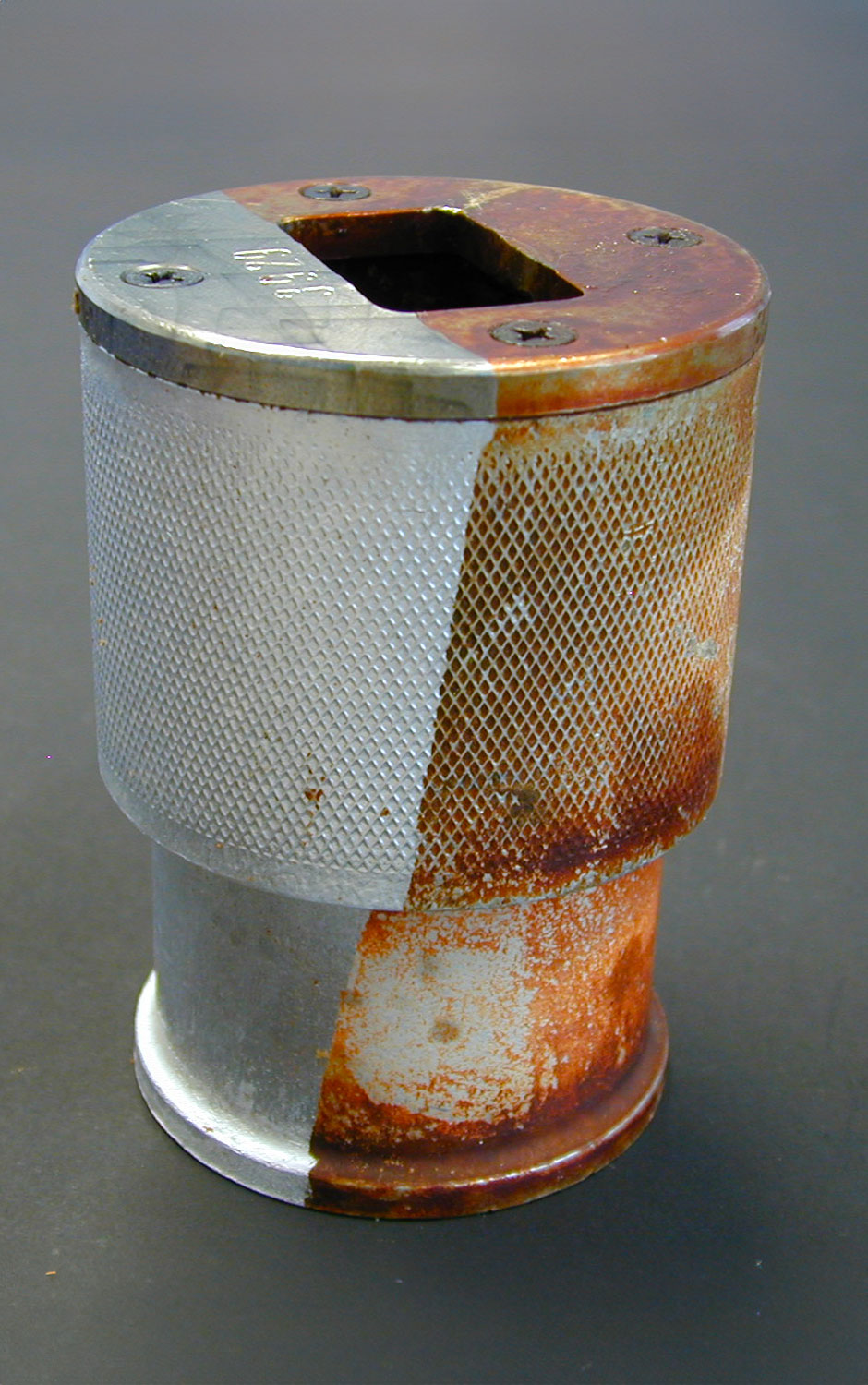

The laser makes it possible to remove many types of coating, painting, coating, oxides etc. very quickly, but also to sublimate all kinds of residues present on the surface: grease, oil, dust, residues, etc. This can be done completely or partially, depending on the application.

The laser technique is a no-contact/non-abrasive process with very low heating of the treated area. No chemical agents are used. Depending on the power used, we can remove between 1 mm and 2 mm of layer in one go and localize the treatment by band, by zone, etc. Once the intended layer is reached, the substrate will not be damaged by the laser.

The laser makes it possible to remove many types of coating, painting, coating, oxides etc. very quickly, but also to sublimate all kinds of residues present on the surface: grease, oil, dust, residues, etc. This can be done completely or partially, depending on the application.

The laser technique is a no-contact/non-abrasive process with very low heating of the treated area. No chemical agents are used. Depending on the power used, we can remove between 1 mm and 2 mm of layer in one go and localize the treatment by band, by zone, etc.

Once the intended layer is reached, the substrate will not be damaged by the laser.

The laser precision mould cleaning process is an excellent economical, automatable and environmentally friendly alternative to traditional methods. This ecological process quickly and safely removes difficult residues without producing chemical or abrasive waste.

The laser technology can be adjusted very precisely for the surface treatment of metallic materials. This offers the possibility to apply powerful high intensity laser pulses to create precise micro-structures of various types for visual and mechanical effects.

Virtually all types of materials can be marked with laser marking systems: metals, plastics, semiconductors, glass sheets and ceramics as well as organic surfaces such as wood, paper and leather. Depending on the intensity of the laser beam on the substrate, the desired marks can be produced by colour change, engraving or micro-fusion.

Laser technology is a remarkable and unique tool for architectural restoration and conservation. Laser cleaning has proven to be the most gentle and effective method for restoring historic architectural treasures, such as sculptures, ornate bronze and terracotta statues, as well as the facades of entire buildings.

Laser cleaning removes harmful and unsightly deposits without chemicals, abrasives, water, dust or residue, which could pose a risk to people and the planet.

LPC Engineering

Smart Cleaning Starts with Smart Engineering

- 6 rue Pierre Risch, L-5450 STADTBREDIMUS

- +352 671 270 596

- info@lpc-engineering.com