Automotive industry

Production machines

Keep your production machines free from contaminants that can affect their performance and longevity. Our cleaning technologies effectively remove grease, oil and other residues without damaging sensitive components.

Conveyor belts

Keep your conveyor systems running smoothly with thorough, non-abrasive cleaning that extends belt life and prevents production delays.

Electrical components

Safely clean live areas such as control cabinets and fuse boxes, without risking short-circuits or damage to equipment.

Molds and matrices

Accurate and thorough cleaning of molds and matrices, essential for high-quality molding and casting processes. Our technologies guarantee the removal of all residues and preserve the integrity and precision of your molds.

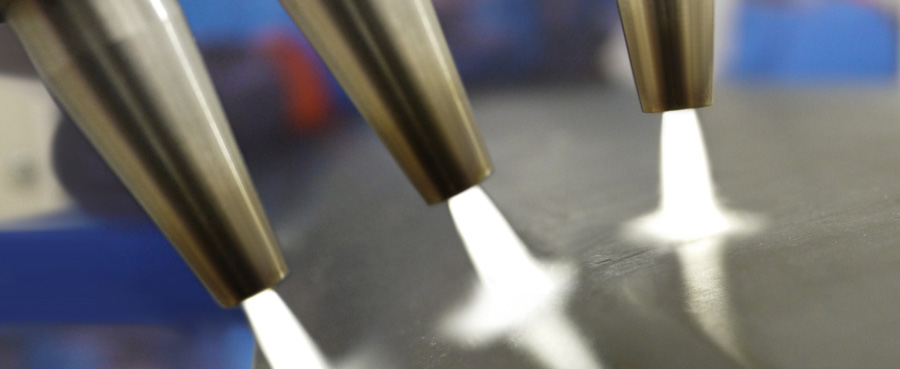

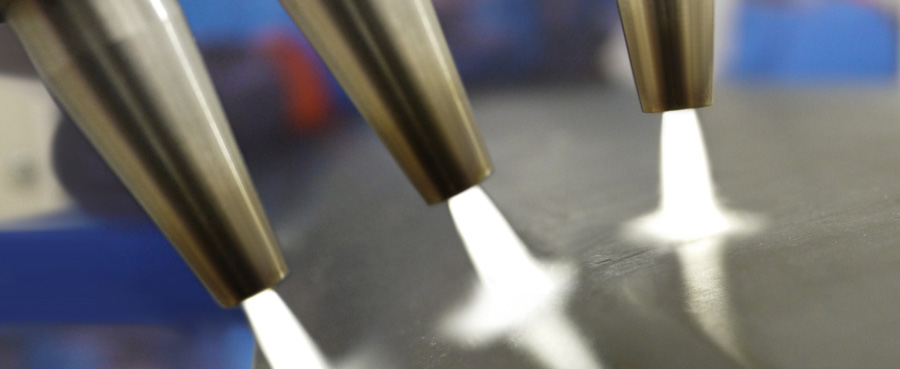

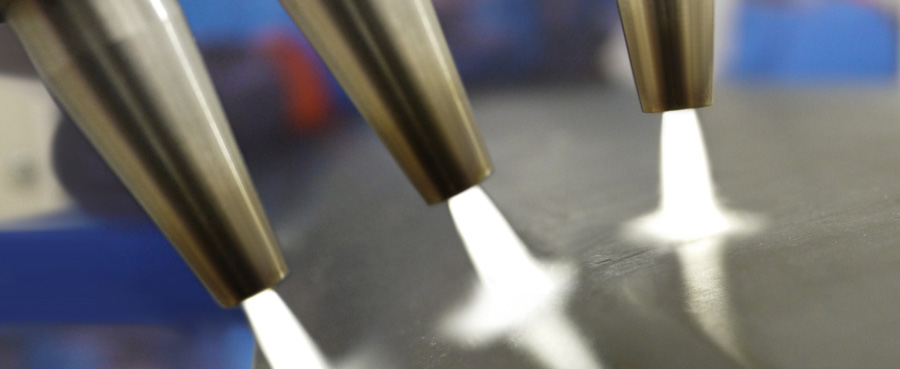

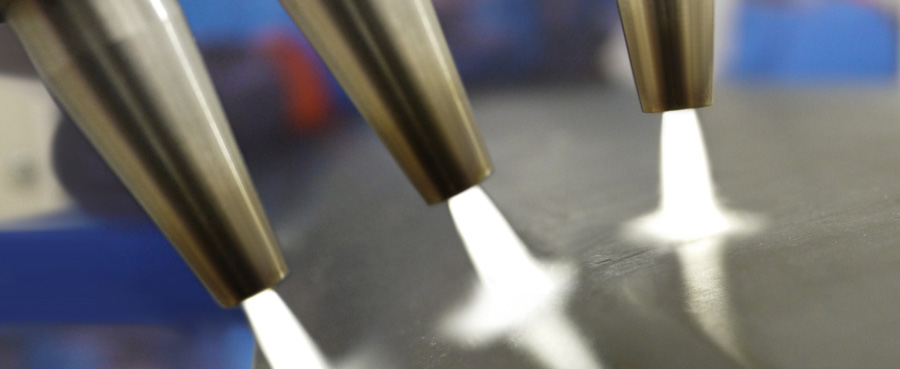

Surface preparation

Prepare material surfaces for painting, bonding or coating with our ecofriendly technologies. Achieve optimal surface conditions that improve adhesion and finish quality.