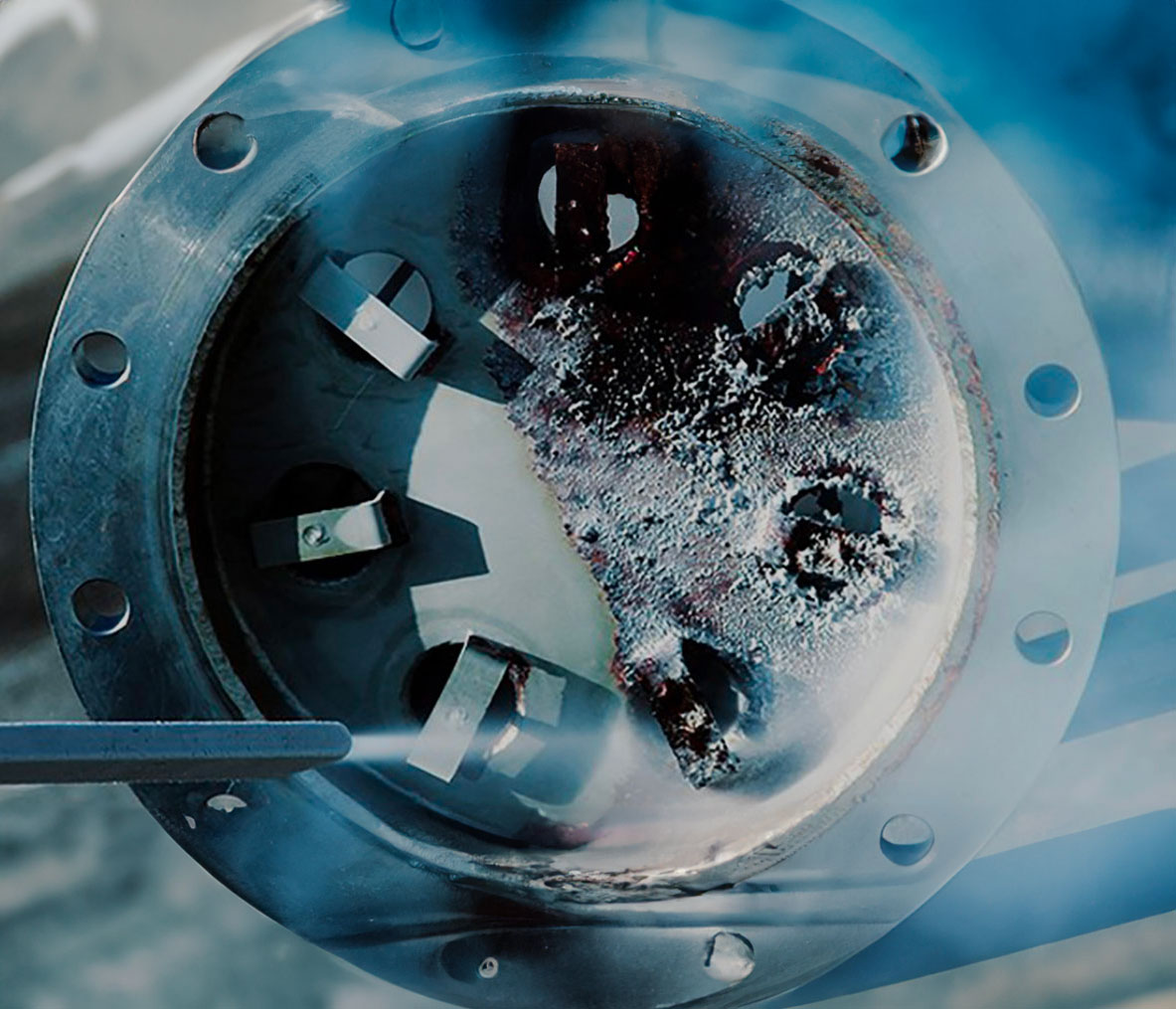

Dry ice cleaning

Dry ice cleaning

Dry ice blasting has significant advantages on two levels:

- Not only by impact but also by the abrupt cooling by CO2 (-78°C), the upper layer to be treated contracts and comes off easily.

- Moreover, the CO2 used by this process is eliminated without any treatment operation, by simply returning to a gaseous state (the beads sublime in the air after blasting).

No residue

Ecological

Gentle cleaning

Principle

Most of the equipment can be cleaned on site without dismantling, without waiting for it to cool down. Here are the operational advantages of this process:

- Improve the quality of production.

- Avoid health and safety issues from toxic solvents and thus provide a healthier working environment.

- Reduce cleaning times, production costs, preventive maintenance, equipment repair costs and production interruptions.

- Avoid humidity. Eliminate secondary waste and the cost of disposal.

- Extend equipment life by minimizing surface abrasion.

- It is a non-abrasive, non-flammable and non-conductive cleaning process.

- It is environmentally friendly and free of secondary contaminants such as solvents or gravel.

- It is clean and approved for use in the food industry.

- Allows most items to be cleaned on site, with no time lost for disassembly.

- Can be used without damaging active, electrical or mechanical parts or creating fire hazards.

- Can be used to remove production residues, release agents, contaminants, paint, oil and biofilm.

Contact us by phone for any questions: +352 671 270 596

Applications

Get a free consultation

Contact us by phone for any questions:

The use of dry ice blasting generates very significant savings for the industry thanks to a considerable reduction of the cleaning time of welding lines, moulds for plastic, rubber, metal and PU parts, electric motors, fans, structural elements, maintenance and general upkeep.

A considerable advantage of this cleaning technology is that it can be automated. In fact, by defining the operating parameters, the cleaning is very stable, homogeneous, always efficient and very fast without rejecting particles to be reprocessed.

Dry ice blasting is applied in various sectors of the food processing industry, such as food and beverage production, the chocolate industry, industrial bakery, pizza and pasta production, extrusion baking, ready-made foods, animal feed, etc.

- Very fast and effective method

- Non-abrasive and dry cleaning

- Ecological & economical

Dry ice blasting is highly recommended for cleaning live and non-voltage equipment, such as rotors and transformers, turbines, transformers and substations, AC/DC engines, electrical cabinets, nuclear decontamination, etc.

Dry ice blasting is applied in various industrial sectors, especially in the maintenance field. Indeed, before, during or after a maintenance intervention on an installation, dry ice blasting is very effective. The cleaning can take place under tension, can reach all areas and can be done very quickly.

LPC Engineering

Smart Cleaning Starts with Smart Engineering

- 6 rue Pierre Risch, L-5450 STADTBREDIMUS

- +352 671 270 596

- info@lpc-engineering.com